Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Function: LAMINATE

Automatic Laminator Machines and Panelizing Machines from Union Tool.

Laminate, glue up, lay up, layering... different terms for making sandwiches of core substrate material with facing sheets on one or both sides. This general principle underlies many processes from film lamination to laying up wall, ceiling and floor panels. Pressure roll laminator machines frequently follow glue spreading or coating operations in a production line; for that reason, many of the automatic laminator machines and panelizing machines illustrated below have companion machines in our Coat and Glue sections. Union Tool panelizers and laminating machines are available in roll widths from 6" to 120".

Here are a few samples that illustrate the LAMINATE function in action:

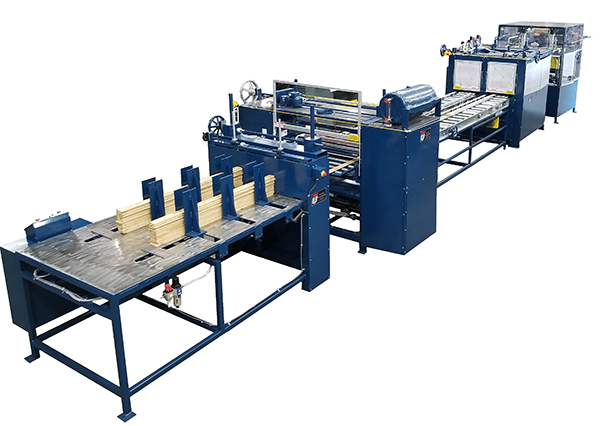

ENGINEERED FLOORING SYSTEM - A complete material handling and coating system for the production of engineered flooring. Includes dual-lane core feeders, hot melt roller coaters, lay-up conveyors, multi-nip rotary laminators and flying cutoff saws. Union Engineered Wood Flooring Systems are available for single- or dual-lane operations.

MULTI NIP ROTARY LAMINATOR - Union Tool has designed a Multi-Nip Rotary Laminator for Engineered Flooring that combines high pressure rolls with hold down rolls to insure proper bonding of Laminated Flooring.

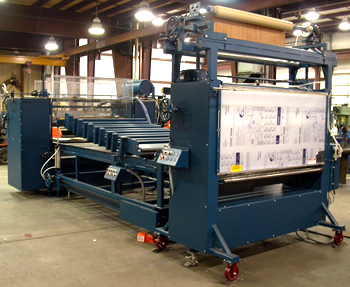

The second picture shows a Nine (9) Nip Machine that incorporates high pressure nip points at the entry and exit nip points. The high pressure nip points use 6.5” diameter rolls with the top rolls adjustable in relationship to the bottom rolls from 0 to 3”. Each nip point at the exit and entry end of the machine utilizes two (2) 6” diameter air cylinders attached to the top roll to provide the pressure. The middle section of the machine incorporates 4” diameter hold down rolls. The top hold down rolls are also adjustable in relationship to the bottom rolls and use two 6” diameter air cylinders to raise and lower the top hold down roll section. The hold down section allows the hot melt adhesive to cool down and provide necessary green strength for the next production process. This 9 Nip Rotary Laminator can laminate at speeds up to 100 feet per minute.MULTI NIP ROLL MACHINE - Union Tool has designed a Multi Nip Roll Machine that is used in various industries in laminating door panels and Engineered Flooring. By utilizing a series of rolls the laminating panel will be under the pressure longer and can have various amounts of pressure using different sections of the machine. Pneumatic air cylinders provide the down pressure. Several sets of cylinders provide the varying pressures. Rubber and steel rolls are used with the upper roll adjustable in relationship to the lower rolls from 0 to 2". Union Tool builds this Multi-Nip Roll Machine in a three (3) set, five (5) set, and ten (10) sets of rolls machine.

UNION VENEER/VINYL LAMINATING SYSTEM - Boost productivity and product quality with this Union equipment package. This Veneer/Vinyl Laminating System contains a Union Hot Melt Roller Coater, Union Powered Lay-up Conveyor and Union Rotary Laminator to laminate several different core materials to a variety of different veneers and vinyl materials.

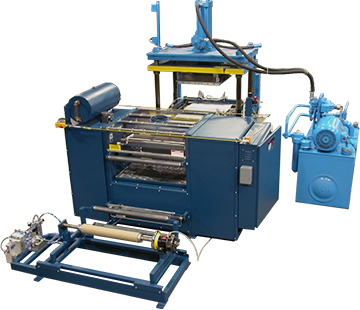

AUTOMATIC HITCH-FEED LAMINATOR SYSTEM

FOR COATING PUR HOT-MELT TO WEB-FEED ARTWORK - This complete laminator system pulls artwork from an unwind station and coats the top surface with PUR hot-melt adhesive in a specified area, then pulls the spot-coated artwork into a hydraulic die-cut and lamination press.

HOT ROLL LAMINATOR - Union Tool hot roll film laminators speed production line application of protective films to one or both sides of EPS foam cores. The programmable controller assures tight tolerances for both roll temperature and line speed. Processes foam cores up to 4' wide by 12' long.

110-inch ROTARY LAMINATOR - A really big rotary laminator for wall panels, ceiling panels and floor panels in the recreational vehicle (RV), mobile home, and fifth-wheel towables industries. Provides laminating pressure for panel sandwiches of substrate cores and facing sheets. Combined with the Union Tool 110" Dual Head Hot Melt Roller Coater, this panel laminating machine makes a complete laminating station for very large panels.

ROTARY PINCH ROLL LAMINATOR for substrate lamination - A pinch roll rotary laminator to exert bonding pressure to laminate two substrates or web materials together. Accepts material up to 50" wide (Union Tool laminators are available up to 120" wide.)

MULTI-NIP ROTARY LAMINATOR with unwind stand - 3-nip roll machine where substrates sent through will be nipped three times within the framework of the machine. Unwind stand is mounted directly above the lamination rolls.

ROTARY LAMINATOR for metal gasket flattening - A rotary laminator to flatten metal gasket edges.