Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Union Tool Company News

Union Tool Marks 80 Years of Innovation, Adaptability, and Family Values

Union Tool, a pioneering force in the manufacturing industry, proudly celebrates its 80th anniversary, a remarkable journey that began in 1944 under the visionary leadership of founder Karl J. Heinzelman. From its inception as a wood-centric enterprise to its current status as a global leader in customized lamination manufacturing solutions, Union Tool's resilience, innovation, and commitment to family values have defined its success.

The company's adaptability is a testament to its ability to evolve with the times. Originally focused on wood-related industries, Union Tool diversified to accommodate the changing landscape of materials, including plastics, metals, and composites. This ability to adapt to the needs of evolving technologies and industries has been a key driver of Union Tool's continued success.

Union Tool takes pride in its comprehensive approach to manufacturing. With design and build processes all under one roof, the company maintains total control over every aspect from design to final installation. This ensures the highest quality and precision, a factor that has contributed to Union Tool's global reach, shipping its products worldwide.

The essence of Union Tool's success lies in its ability to customize solutions for nearly every customer. The company's engineering department, comprising experts in mechanical and electrical design alongside software development, plays a pivotal role. Innovative designs undergo rigorous testing, ensuring optimal performance under actual production conditions.

Union Tool's commitment extends beyond machinery; the company understands the entire production process, from sheet feeders and automatic stackers to roller coaters, laminating machines, and complete lamination systems. The result is machinery that not only enhances efficiency but also reduces waste, labor costs, and repairs, ultimately improving uptime and productivity.

Reflecting on the company's 80-year journey, Union Tool acknowledges the invaluable contributions of its past and current employees. The legacy of dedication and hard work has been instrumental in Union Tool's enduring success. The company invites everyone to join in recognizing the collective efforts that have shaped Union Tool into the thriving business it is today.

Looking ahead, Union Tool remains committed to innovation. While keeping specifics under wraps, the company reveals that its engineers are currently developing new technologies to meet the demands of an ever-changing market. This commitment to staying at the forefront of technology underscores Union Tool's dedication to providing cutting-edge solutions for its customers.

As Union Tool marks its 80th anniversary, the company remains a symbol of resilience, innovation, and unwavering dedication to its customers. The celebration is not just a reflection of the past but a testament to the company's commitment to shaping the future of manufacturing.

New Vacuum Bag Press Lamination System

Union Tool is excited to announce we have designed a new Vacuum Bag Press Lamination System to compliment our current Hot Melt Lamination Equipment specifically for the RV Industry. We can now be your “One Stop Shop” for all your laminating requirements in producing laminated panels for RV production.

Our new design for both the Liquid PUR Dispensing Head and Four Table Bag Press will incorporate new technologies and updated components to make the laminating process much easier on the operators and maintenance personnel operating this equipment.

Some of the new features include:

- Hydraulic Guided Rail System for smooth vertical movement of the Bag Press.

- Two (2) 15” Touchscreen Operator Control Panels with a single PLC and remote racks.

- Drop In Idler Conveyor Rolls for easing cleaning and maintenance.

- Electronic Glue Valve Assembly to control adhesive dispensing.

- Six Linear Transducer Sensors for accurate positioning on the Bag Press.

- Light Curtain Safety System.

- Custom Length Systems up to 50 feet long.

- LOCALLY MANUFACTURED AND LOCALLY SERVICED AND SUPPORTED.

Union Tool will provide the same excellent support and service you have come to know with our Hot Melt Lamination Equipment. We are known as the #1 Manufacturer of Hot Melt Lamination Equipment in the RV Industry and intend to bring that same motto to Vacuum Bag Lamination Equipment for the RV Industry.

For more information please contact Union Tool via our sales submission form or by calling 574-267-3211.

Management Changes at Union Tool

The Union Tool Corporation announced a series of management changes to its family-owned business, started by Karl J. Heinzelman in 1944. Nick Simpson and Chas Simpson, both fourth-generation family members, become vice presidents of Union Tool. Co-President Mike Simpson has retired though will remain a consultant for the company and will continue his role servicing his long-time customers. President Chuck Simpson - “This company has succeeded as well as it has in a very large part because of Mike’s 45-year effort. We are proud of that effort and proud of him. Meanwhile, my two sons Chas and Nick are ready to continue those efforts as we look forward to an even brighter future. In fact, our sales are at record levels and that’s exciting for the entire company.”

The Union Tool Corporation manufactures automated machines and equipment to handle and process flat sheets, boards and panels made of wood, metal, glass, plastic, fiber, foam and other materials in a conveyorized processing line. Machines and equipment include roller coaters, feeders, stackers, de-stackers, hot melt applicators, laminators and lubricators. Union Tool Corporation also provides custom manufactured equipment for a diverse group of industries worldwide.

New Flooring Roller Coater/Laminating Equipment

The Union Tool Corporation now offers equipment for coating and laminating a variety of flooring products. Union Tool Roller Coaters are used in the production of Luxury Vinyl Tile (LVT) as well as Engineered Flooring and Carpet. These Roller Coaters apply a controlled and consistent amount of hot-melt or water-based adhesive to LVT product to laminate a foam or backer material directly to the LVT product.

Single machines or Complete Lamination Production Systems are designed and manufactured by Union Tool. The company offers an in-house testing lab that allows customers to bring or send various flooring products and adhesives for testing on production-sized Lamination Equipment. This is a value-added service that customers appreciate.

77-year-old Union Tool Corporation manufactures automated machines and equipment to handle and process flat sheets, boards and panels made of wood, metal, glass, plastic, fiber, foam and other materials in a conveyorized processing line. Machines and equipment include roller coaters, feeders, stackers, de-stackers, hot melt applicators, laminators and lubricators.

New Union Tool Flying Cutoff Saw

The Union Tool Corporation has designed a Flying Cutoff Saw that can be incorporated into the engineered wood flooring lamination system. This saw is manufactured to cut laminated engineered flooring planks as they exit the Union Five Nip Rotary Laminator. The Union Flying Cutoff Saw allows for continuous lamination at speeds up to 50 feet per minute.

With incorporating dual sensors, the saw will detect a gap in the top veneer layer that was created by the operator at the layup station placing the veneer onto the coated surface of the core. In a smooth downward motion, the saw will make a cut when each gap is detected.

The Union Tool Corporation manufactures automated machines and equipment to handle and process flat sheets, boards and panels made of wood, metal, glass, plastic, fiber, foam and other materials in a conveyorized processing line. Machines and equipment include roller coaters, feeders, stackers, de-stackers, hot melt applicators, laminators and lubricators. Union Tool Corporation also provides custom manufactured equipment for a diverse group of industries worldwide.

Fourth Generation Joins Union Tool

The Union Tool Corporation proudly welcomes another member of the fourth generation to its family-owned business, started by Karl J. Heinzelman in 1944. Nick Simpson joins Union Tool after working several years in hospitality sales in Bloomington, IN for a leading hospitality company. During that time, Simpson was promoted to several roles including sales manager, senior sales manager, and director of sales. He graduated from Ball State University in 2014 with a Bachelor of Science degree with a focus on Professional Selling. Nick Simpson joins his brother, Chas Simpson, as a member of the fourth generation to be working at Union Tool. Co-Presidents Chuck Simpson and Mike Simpson represent the third generation.

The Union Tool Corporation manufactures automated machines and equipment to handle and process flat sheets, boards and panels made of wood, metal, glass, plastic, fiber, foam and other materials in a conveyorized processing line. Machines and equipment include roller coaters, feeders, stackers, de-stackers, hot melt applicators, laminators and lubricators. Union Tool Corporation also provides custom manufactured equipment for a diverse group of industries worldwide.

Union Tool Roller Coaters for the Bedding Industry

The Union Tool Corporation offers roller coaters to apply a controlled and consistent amount of adhesive to various foam material for the bedding industry. The adhesive can be applied to one or both sides of the foam material. Standard features of these roller coaters include single hand wheel adjustment with indicator readouts, A.C. variable speed drive, chrome plated rolls and safety guards with interlocks.

The Union Tool Corporation has been designing and building roller coaters and laminating equipment for over 73 years. Machines are available in many different sizes from small (14" wide), to medium (50" wide), to large (110" wide), and all sizes in between.

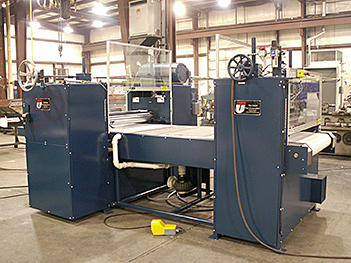

Union Hot Melt Roller Coater/Hot Roll Laminator Combo Machine

Union Tool Corporation has designed a new Lamination machine for the Expanded Polystyrene Industry (EPS) that combines the use of a Hot Melt Roller Coater, to apply hot melt adhesives, and a Hot Roll Laminator, to laminate adhesive backed films, in one machine.

This machine has the capability of laminating EPS sheets to roll materials that require a hot melt adhesive coating, as well as roll materials that already have an adhesive coating on them and only require heat to activate the adhesive.

A range of products can be laminated to the EPS using the hot melt roller coater, including roofing materials, paper, packaging materials, fiberglass, non-woven materials and fabrics or textiles. When utilizing the Hot Roll Laminator portion of the machine, adhesive backed films and foils are easily laminated through the heated Teflon coated laminating rolls.

By combining these two different laminating processes, the production floor space is greatly reduced and labor savings can be achieved, which provides reduced equipment and operation costs for Union Tool customers.

Machine Code #SO18547.

Union Tool Corporation Celebrates 70th Anniversary

The Union Tool Corporation proudly celebrated its 70th anniversary in 2014. Started by Karl J. Heinzelman, Union Tool is a family-owned business. Co-presidents Chuck Simpson and Mike Simpson represent the third generation, while the fourth generation started in October when Chas Simpson joined the company after earning an MBA from Ball State University and working several years in the Indianapolis area. “Not many family businesses make it three generations and we’re proud we did,” said Chuck Simpson, Co-President of Union Tool. “And now that we are bringing in a fourth generation? That’s pretty rare. We’re looking forward to keeping their tradition alive long into the future.”

Union Tool Corporation manufactures automated machines and equipment to handle and process flat sheets, boards and panels made of wood, metal, glass, plastic, fiber, foam and other materials in a conveyorized processing line. Machines and equipment include roller coaters, feeders, stackers, de-stackers, hot melt applicators, laminators and lubricators. Union Tool Corporation also provides custom manufactured equipment for a diverse group of industries worldwide.

New Hot Melt Roller Coater/Laminator for Floor Mats!

In order to provide the equipment best suited to meet the customer’s needs, The Union Tool Corporation designed and constructed a system that utilizes a Union Hot Melt Roller Coater and a Union Dual Pinch Rotary Laminator (Pinch Roll). The coater and the laminator are tied together with a through conveyor utilizing a perforated belt and vacuum hold down under the coating area. This insures that the floor mat materials are transported under the coating head where a controlled amount of hot melt adhesive is applied to the top surface only. After the rubber flooring substrate has been coated, it is transported to an open area on the conveyor between the coater and the laminator. A sensor detects the trailing edge of the coated substrate and stops the conveyor in a pre-determined position. This area allows the top cover to be positioned on the coated floor substrate before being transported into the laminator.

When the top cover has been placed on the coated surface, the operator activates the through conveyor. The conveyor then transports the lay-up into the Union Dual Rotary Laminator. The laminator then applies the bonding pressure to makes sure that the glue line makes good, even contact with the bottom coated floor substrate. The process is then complete and the laminated floor mat can then be stacked and are ready for further operations.

The system is complete with all operator controls and safety features that allow for safe, easy set-up and operation.