Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Coaters

In-Line Stock Lubricator

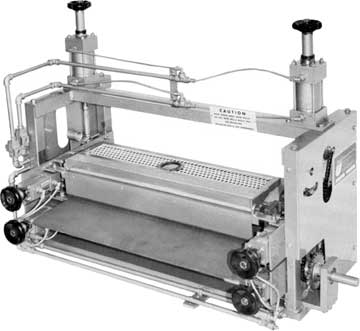

Union Tool Inline Stock Lubricators apply a precise film coating of drawing compound or stamping lubricant to metal blanks and sheets just before they enter the stamping or drawing press. These compact units go between the stock feeder (typically a coil straightener) and the press.

In the Model B Double Coater Roll Configuration, the liquid coating for the top surface is held in the trough between the top coating roller and its companion doctor roll; the liquid coating for the bottom surface is held in a pan in which the bottom coating roll and its companion doctor roll both run.

Synonyms

These are sometimes called lubrication applicators, metal blank lubricators, sheet lubricators, stamping lubrication applicators, drawing compound applicators, or stamping lubricators.

Operational Description

The Union Inline Stock Lubricator was developed to apply a controlled film of drawing compound or stamping lubricant to de-coiled or sheet metal stock as it is presented to the press.

These compact units were designed to fit in the confined area between the press feed rolls and the press face. They may be manufactured in any width necessary to handle the maximum stock capacity of the press.

The Union Inline Stock Lubricator incorporates two neoprene-covered coating rolls which work in conjunction with two chrome-plated steel metering rolls. By adjusting the metering rolls, a controlled film of lubricant is applied to the stock.

Mechanical stops and air cylinders are standard equipment on the unit for precisely controlling the position of the rolls. The air cylinders may be tied into the main power supply for the press so that the rolls will automatically open when the system is not in operation. Power is normally transmitted through a sprocket and chain arrangement which is attached to the existing feed rolls.

A complete recirculating system may be furnished to supply the lubricant to the coating areas with overflow tubes to return the excess to the sump tank. By controlling the film thickness and recirculating the lubricant, the messy drip-squeeze method is eliminated, which creates a safer working area and also a cost reduction obtained by retaining lubricant which previously would have spilled onto the floor. Greater die life is another benefit of the controlled film application feature of the Union Stock Lubricator.