Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Industry: METAL

Metalworking, metal forming and metal stamping.

Metal forming and stamping operations typically call for applying an even coating of drawing compound or stamping lubricant to metal blanks, plates or sheets before they go into the press. Loaders, stackers, feeders and de-stackers must deal with the weight of metal plates, which can be considerably more than other materials like wood, fibre and foam. Union Tool makes many machines for handling and processing metal sheets and blanks.

Union Tool machines for metal working, forming and stamping:

DUAL HEAD STEEL STRIP UV ROLLER COATER - This dual-head reverse roll coater is designed to apply an extremely smooth, controllable, pinhole-free application of UV and other coatings to one or both sides of steel strips.

STEEL BLANK SHEET FEEDER - This Union Tool Steel Blank Sheet Feeder destacks and loads steel blanks onto a feed table, such as for an automatic CNC punch machine. It features precision placement of the blank to within 1/16" (0.0625', 1.5875 mm)

AUTOMATIC METAL SHEET FEEDER - This automated sheet feeder accepts a stack of metal sheets or blanks and feeds them one at a time to a conveyor line or a processing machine. The infeed stack is automatically indexed up to the correct pass line height as each sheet is fed.

AUTOMATIC VACUUM SHEET FEEDER - This automated vacuum sheet feeder accepts a stack of wood, plastic or metal sheets and feeds them one at a time to a conveyor line or a processing machine. The infeed stack is automatically indexed up to the correct pass line height as each sheet is fed.

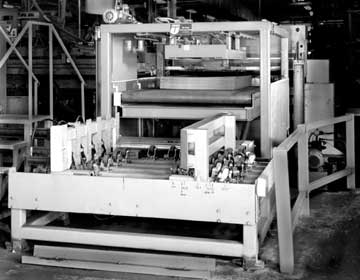

METAL SHEET PINCH ROLL FEEDER - This heavy-duty feeder is actually a dual station de-stacker that accepts a pair of 150-sheet stacks of steel and feeds them into a forming machine a sheet at a time using vacuum cups to lift the sheets up to pass height, and then feeding them into the former through a set of heavy pinch rollers.

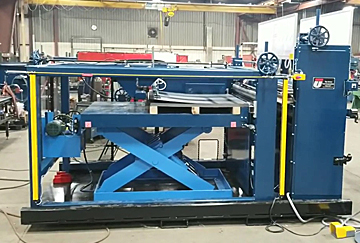

METAL SHEET VACUUM FEEDER - Feeds metal sheets one at a time from an integrated lift table carrying a stack of sheets weighing as much as a ton. The lift table indexes the sheet stack to pass line height, magnetic sheet fanners separate each sheet, and vacuum cups transfer the sheets to the conveyor.

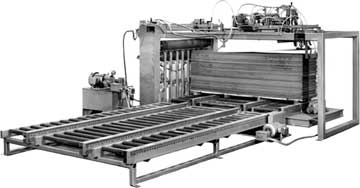

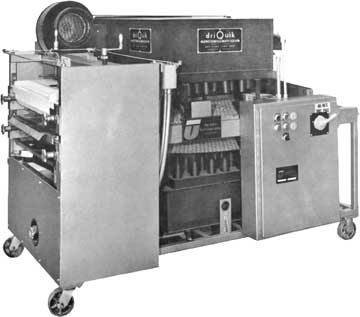

PRESS BLANK FEEDER COATER - A combination metal blank de-stacker, drawing compound coater, and blank feeder all in one machine makes the Union Tool Press Blank Feeder Coater a natural for metalforming and metal stamping operations.

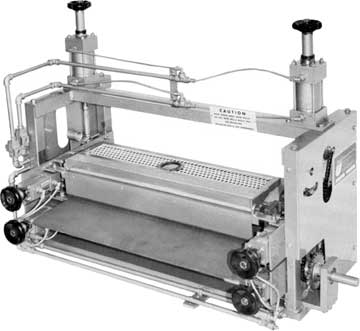

METAL BLANK IN-LINE STOCK LUBRICATOR - Union Tool Inline Stock Lubricators apply a precise film coating of drawing compound or stamping lubricant to metal blanks and sheets just before they enter the stamping or drawing press. These compact units go between the stock feeder (typically a coil straightener) and the press.

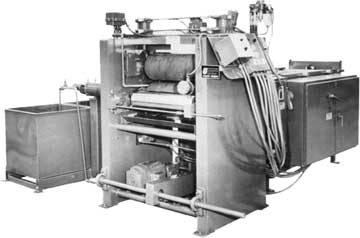

LUBRICATON ROLLER COATER - FLASH-OFF DRYER - A metal blank lubricant roller coater with integrated flash off dryer ovens (top and bottom). Lubricates and dries metal blanks prior to drawing or stamping operations. The flash-off dryer ovens combine infrared heat and moving air to flash dry the coated blanks; variable heat.

ROLLER COATER for STAMPING LUBRICANT and DRAWING COMPOUND application - A roller coater for the application of drawing compound or stamping lubricant to metal sheets prior to metal forming operations. Includes infeed and outfeed conveyors. Coats top side, bottom side, or both in a single pass.

ROLLER COATER Series 45 - Model A - An extremely rugged, heavy-duty roller coater for applying lubricant to heavy gauge hot roll blanks.

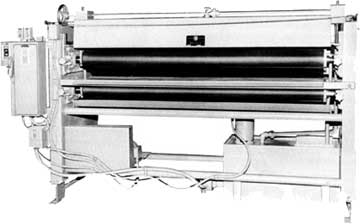

ROLLER COATER Series 45 - Model B - An extremely rugged, heavy-duty roller coater for panels, sheets and coils up to 98" wide and up to 2" thick. For coating lubricants, drawing compounds, and synthetic oils.

DUAL STATION STACKER - This dual station stacker stacks metal blanks as they come from a coil-fed blanking press, loading an operator-designated number of blanks onto each of two stacking carts. When the first cart is filled, the machine automatically switches over to filling the second cart.

ROTARY LAMINATOR for metal gasket flattening - A rotary laminator to flatten metal gasket edges.

SELF CLEANING ROLLER COATER - A stainless steel through conveyor belt with an integrated scrubbing brush roller and squeegee is the key to keeping things clean as the central roll coater mechanism applies a thin film of adhesive coating to the top surface of the gasket substrate material.

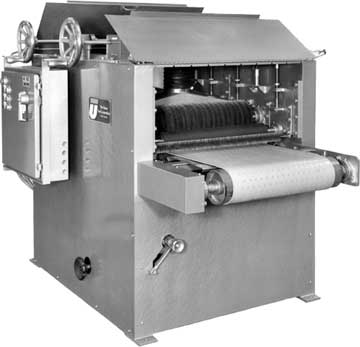

WIRE BRUSH MACHINE for brushed aluminum finishes - Covers the surfaces of aluminum sheets with a handsome brushed aluminum texture. Dual stainless steel brushes apply a scratch finish texture on aluminum sheets to produce that "brushed aluminum" look.