Special Functions

- Industries & Applications

- Union Tool FAQs

- UTC Literature and Manuals

- Leasing Options

- Get an Equipment Quote

Machine Functions

- Feeding Machines

- Moving Machines

- Coating Machines

- Gluing Machines

- Laminating Machines

- Stacking Machines

- Specialty Machines

Industry/Applications

Function: GLUE

Glue Spreaders, Glue Application Machines and Hot Melt Roller Coaters from Union Tool.

Sticking sheets and panels together is central to industries like woodworking, cabinet making, furniture building, and RV, mobile home, and fifth-wheel towables manufacturing, not to mention manufactured housing. Adhesive spreaders, glue application machines and hot melt roller coaters are primary tools in these glue up operations... Union Tool makes roller coaters in roll widths from 6" to 120".

Here are a few samples that illustrate the GLUE function in action:

110" WIDE HOT MELT ROLLER COATER (15094) This picture illustrates a Union Series #65, model A, 110" wide Hot Melt Roller Coater. This machine is designed to apply a PUR hot melt adhesive to one or both sides of composite products for the production of RV components. The machine includes a hot oil heating system that heats all four rolls up to 350 degrees Fahrenheit. The upper coating head is adjustable in relationship to the lower coating head from 0 to 4" through the use of a motorized adjustment hand wheel. Silicone covered coating rolls are used to apply the adhesive.

HOT MELT ROLLER COATER (15038) - This Hot Melt Roller Coater used a built-in moving platen to transport and hold down seating material (fabric) through the coater which applied a hot melt adhesive (PUR) to the top surface (backside) of the fabric. After the fabric was coated it would be laminated to the plastic seat using a vacuum press.

The platen was driven separately through the coater by an AC Variable speed motor. Included in the platen were hold down clips that automatically held the front edge of the fabric as the platen moved into the coater. These clips would open on the backside when the platen automatically stopped for the backside operator to remove the coated part. The machine was complete with an operator touch screen which reduced set-up time for the various size parts that were coated.

HOT MELT ROLLER COATER (17457) - This Union Hot Melt Roller Coater was specifically designed to apply hot melt adhesives to interior automotive carpet materials. The machine features a powered Teflon coated conveyor belt that transports the automotive parts through the roller coater. Built-in hold down clips in the conveyor prevents the part from sticking to coating roll as the adhesive is applied. The conveyor belt cycles after an operator on both sides of the machine activate a “go” button. The coated parts will automatically stop in the correct unload position.

HOT MELT ROLLER COATER (SO15131) - This Union Hot Melt Roller Coater is designed to apply a reactive hot melt adhesive (PUR) to one side of a foam backed vinyl (IPO) material used for interior automobile door parts. This coater applies a controlled and consistent amount of adhesive onto a continuous roll of IPO material for a Vacuum Forming operation or to individual die cut parts in a Laminating operation.

The adhesive coating can cover the entire width of the part or only a center section. Chrome plated rolls are used to apply the adhesive. These rolls do not require maintenance and are easier to clean.This machine can be supplied with unwind stand for roll goods or clip down conveyor for die cut parts.

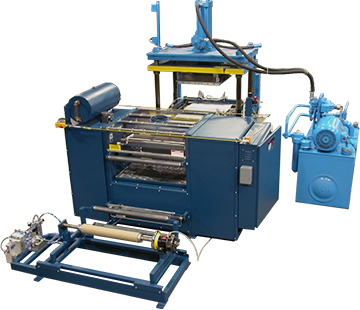

AUTOMATIC HITCH-FEED LAMINATOR SYSTEM

FOR COATING PUR HOT-MELT TO WEB-FEED ARTWORK (PB9353) - This complete laminator system pulls artwork from an unwind station and coats the top surface with PUR hot-melt adhesive in a specified area, then pulls the spot-coated artwork into a hydraulic die-cut and lamination press.

110-inch DUAL HEAD HOT MELT ROLLER COATER (PB4401) - A really big hot melt roller coater for the lamination of wall panels, ceiling panels and floor panels in the recreational vehicle (RV), mobile home, and fifth-wheel towables industries. Coats one side or both sides of the substrate in a single pass; single or double sided coating modes selectable with the flip of a switch. Combined with Union Tool's 110" Rotary Laminator, this makes a complete lamination station for very large panels.

2-SIDED RESIN ADHESIVE ROLLER COATER (PB18453) - An adhesive roller coater designed for applying a precise coating of resin adhesive to both sides of the substrate in one operation.

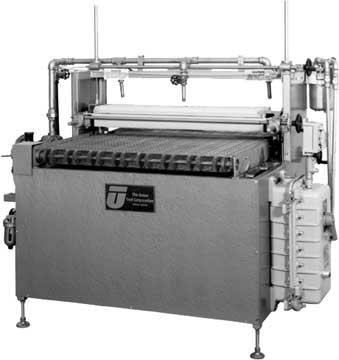

1- or 2-SIDED ADHESIVE ROLLER COATER (PB1977) - An adhesive roller coater designed for applying a precise coating of water-based, solvent-based or phenolic resin adhesive to either side or both sides of the substrate in one operation.

HOT MELT ROLLER COATER, Series #15, Model A (PB20616) - Hot Melt Roller Coater designed to apply hot melt coatings such as wax, contact adhesive, PUR adhesive, pressure sensitive adhesive or virtually any coating material that requires heat for roller coater application.

DUAL HEAD HOT MELT ROLLER COATER (PB310) - This dual head hot melt roller coater applies hot melt to the bottom side, or both sides, of the substrate in one operation. Handles material to 54" wide. Switch between single-sided and double-sided coating with the flip of a switch.